Imagine a critical machine on your production line grinds to a halt. The cause is a single broken part. The real problem? The original manufacturer no longer exists, and the blueprints are long gone. This is a common scenario in manufacturing. In these cases, reverse engineering becomes your most valuable tool.

Through reverse engineering, we deconstruct a finished product. This process allows us to understand its design, learn the original manufacturing process, and discover how to recreate it.

Think of it as a blend of detective work and modern engineering. It allows companies to bring obsolete components back to life. You can also enhance existing designs for better performance. We help you unlock insights hidden within any physical object.

At Projet, we live and breathe these challenges. This guide will explain what reverse engineering is and why it’s essential. We’ll show you how we turn a physical part into a precision-manufactured digital asset.

When is Reverse Engineering the Right Solution?

Reverse engineering isn’t just about copying; rather, it’s a strategic solution for several critical business needs. Consequently, it becomes essential when you need to address specific challenges and unlock new opportunities.

Recreate Legacy Parts

First and foremost, reverse engineering is invaluable when a component is obsolete and its original supplier is gone. In this situation, it is often the only way to produce a compatible replacement. As a result, you can keep valuable, aging equipment operational, thereby avoiding costly system-wide upgrades.Improve Existing Designs

Moreover, by analyzing a part’s design and material, we can identify weaknesses and opportunities for improvement. This process, therefore, allows for the creation of an enhanced version that is stronger, more efficient, or more durable than the original. Ultimately, this leads to better performance and a longer product lifespan.Create Digital Archives

In addition, having a 3D CAD model of your physical inventory is crucial in the age of digital manufacturing. Reverse engineering allows you to create a “digital twin” of a part, which in turn secures its future availability and streamlines the re-ordering process.Understand Original Manufacturing Techniques

Finally, especially for restoration projects, understanding how a part was originally made is key to maintaining authenticity. Reverse engineering provides deep insight into these original methods, while also allowing you to leverage the precision of modern manufacturing for a perfect blend of old and new.

Our Reverse Engineering Process: From Physical Part to Digital Blueprint

At Projet, we specialize in providing top-notch reverse engineering services. Our method combines state-of-the-art technology with decades of hands-on expertise to ensure accuracy and quality.

Step 1: The Scan (Data Capture)

It all starts with a high-precision 3D laser scan. This non-contact process captures millions of data points on the surface of the component, creating a detailed digital “point cloud” that maps every curve, hole, and feature with incredible accuracy.

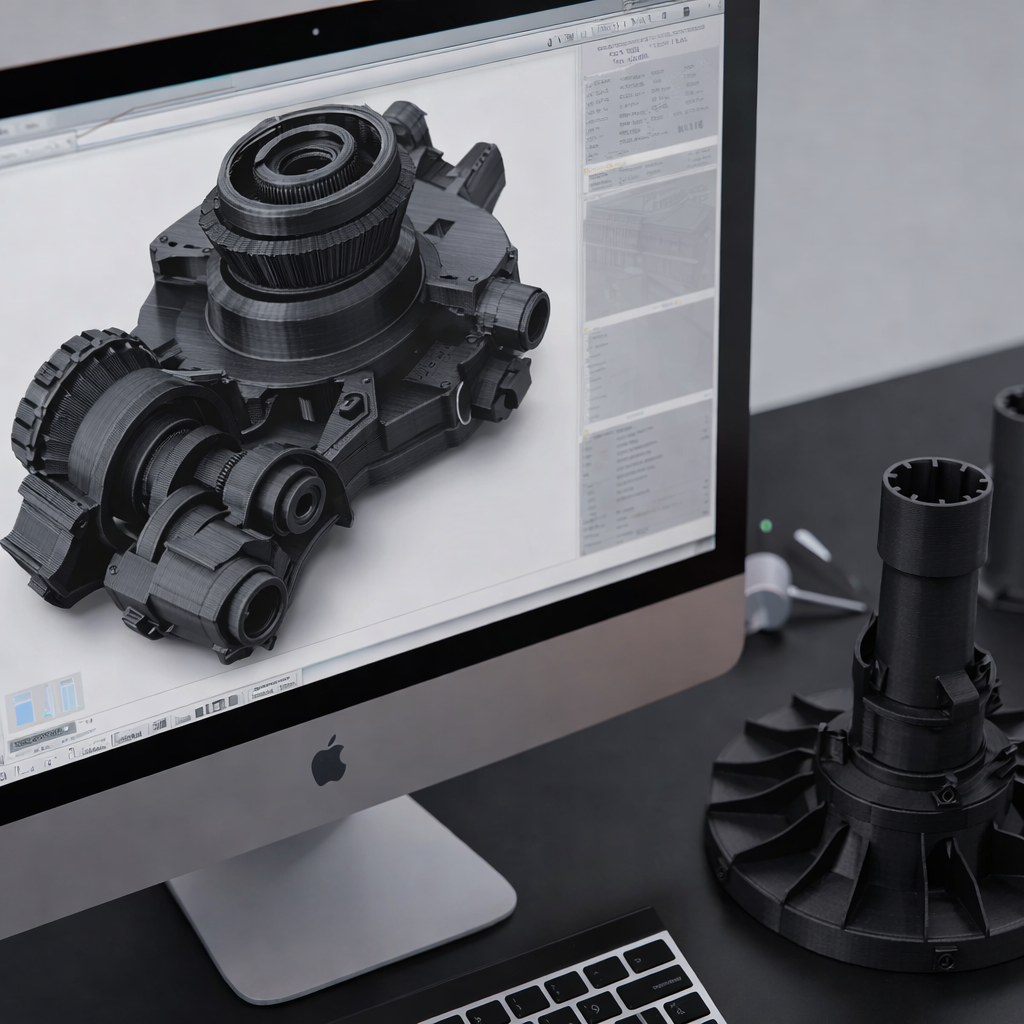

Step 2: The Model (Digital Reconstruction)

Using powerful SolidWorks CAD software, our engineers transform the raw scan data into a fully parametric 3D model. This is more than just a digital replica; it’s an intelligent blueprint that can be modified, tested, and used to generate technical drawings for manufacturing.

Step 3: The Refinement (Analysis and Improvement)

With a precise digital model, we can analyze stress points, evaluate material choices, and make design modifications to enhance performance. This is where we can replicate an out-of-production component and even improve upon its original design for greater longevity.

Step 4: The Part (Manufacturing)

Once the final design is approved, the 3D model is used to manufacture the new component using modern techniques like CNC machining, ensuring the final product meets today’s exacting quality standards.

The Advantages and Challenges of Reverse Engineering

While incredibly powerful, the process is not without its complexities.

| Advantages | Challenges |

|---|---|

| Improved Quality & Performance: Enables detailed analysis and enhancement of the original design and material properties. | Balancing Authenticity & Functionality: Preserving the original look and feel while implementing necessary modern improvements can be challenging. |

| Cost & Time Savings: Often faster and more cost-effective than sourcing from a new supplier or replacing an entire system. | Material Analysis: Accurately identifying the original material composition and heat treatment can be complex. |

| Flexibility & Modernization: Allows legacy designs to be adapted to modern, more efficient manufacturing processes. | Ensuring Compatibility: The redesigned part must integrate seamlessly with existing components. |

| No OEM Dependence: Eliminates reliance on a single Original Equipment Manufacturer for critical spare parts. | Intellectual Property: Legal and compliance considerations must be addressed when dealing with patented or protected designs. |

3D Printing Service Malaysia , 3D Printing service Singapore , 3D Printing service KL , 3D Printing service Selangor, 3D Scanning Malaysia

Why Partner with Projet ?

Selecting the right manufacturing technology is important—but choosing the right manufacturing partner is what truly drives success. Companies across the electronics, automotive, consumer products, aerospace, and medical industries trust Projet because we are more than just a supplier; we are a dedicated partner in their success.

Here’s what sets us apart:

A True One-Stop Solution

We provide a seamless experience by offering a comprehensive suite of manufacturing services under one roof. This integrated approach streamlines your supply chain and simplifies the journey from concept to a market-ready product.

Engineering Expertise You Can Count On

Our experienced engineering team acts as a dedicated extension of your own. We excel at solving complex manufacturing challenges and collaborate closely with you to optimize your designs for quality, cost-effectiveness, and manufacturability.

Flexible Production Volumes to Match Your Needs

Whether you require a single prototype or a high-volume production run, our manufacturing capabilities are designed to scale with your demands. We support your product’s entire lifecycle, from initial launch to full-scale production.

Rapid Turnaround for a Faster Time-to-Market

In today’s fast-paced market, speed is a crucial advantage. We deliver fast, transparent quotes and pride ourselves on our rapid turnaround times, helping you get your innovative products to market sooner.

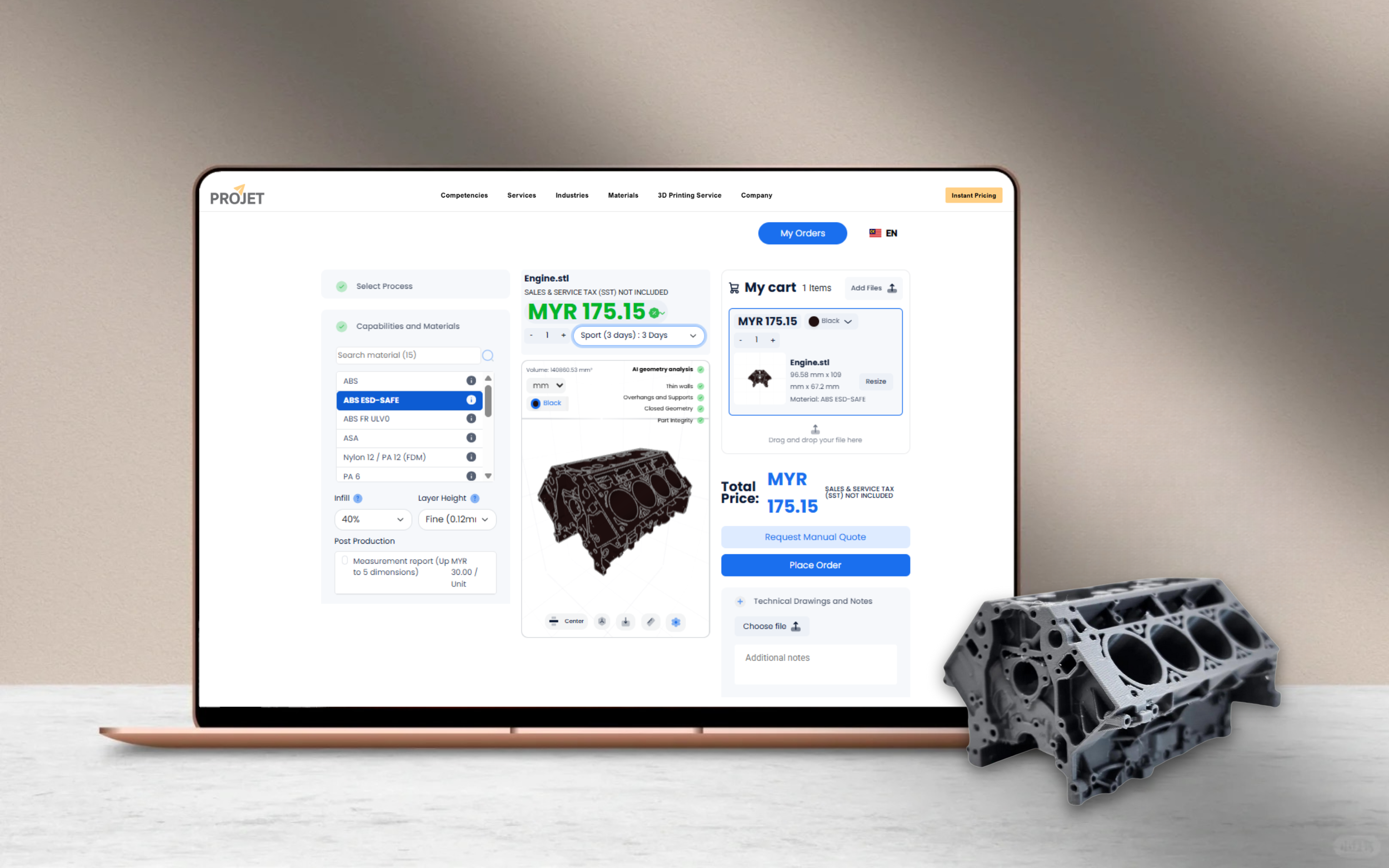

3D Printing Services

Instant Price