In the rapidly evolving world of additive manufacturing (AM), Selective Laser Sintering (SLS) stands out as a powerful technology capable of producing strong, complex, and functional parts. Whether you’re in aerospace, automotive, healthcare, or consumer goods, SLS offers unique advantages that make it a go-to solution for prototyping and end-use production.

What is Selective Laser Sintering (SLS)?

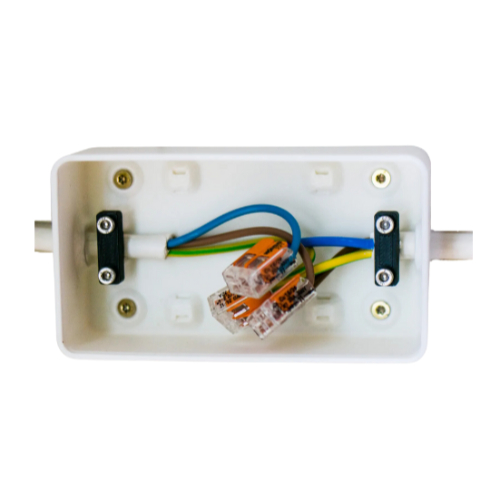

SLS is an additive manufacturing (3D printing) process that uses a high-powered laser to sinter (fuse) fine polymer or ceramic powder particles into a solid structure. Unlike Fused Deposition Modeling (FDM) or Stereolithography (SLA), SLS does not require support structures, allowing for greater design freedom.

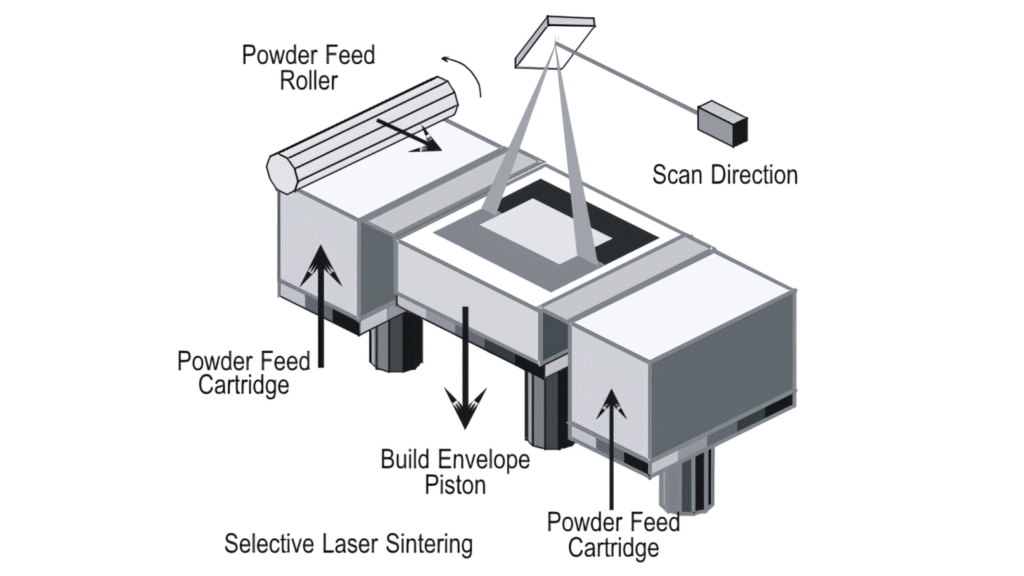

How Does SLS Work?

Selective Laser Sintering (SLS) is a 3D printing process that uses a high-powered laser to fuse powdered material together, layer by layer, to build a three-dimensional object. It’s a powder bed fusion technology, where the laser selectively sinters the powder particles, causing them to bind and solidify. This process eliminates the need for support structures, as the unsintered powder provides support for the printed part.

1. Powder Bed Preparation:

- A thin layer of powdered material, typically a thermoplastic polymer, is spread evenly across a build platform within a chamber.

- The build chamber is preheated to a temperature slightly below the melting point of the powder.

2. Laser Sintering:

- A high-powered laser, guided by a digital CAD model, selectively traces the cross-section of the desired part on the powder bed.

- The laser’s heat fuses the powder particles together at the traced locations, solidifying that layer.

3. Layer Building:

- After one layer is sintered, the build platform lowers slightly, and a recoater mechanism spreads a fresh layer of powder over the previous one.

- The laser then traces the next layer’s cross-section, fusing it to the layer below.

4. Part Completion:

- This process of powder spreading and laser sintering is repeated layer by layer until the entire part is built.

5. Cooling and Post-processing:

- The build chamber is allowed to cool down, and the part is then removed.

- Excess powder is removed, and the part may undergo further post-processing, such as surface finishing or cleaning.

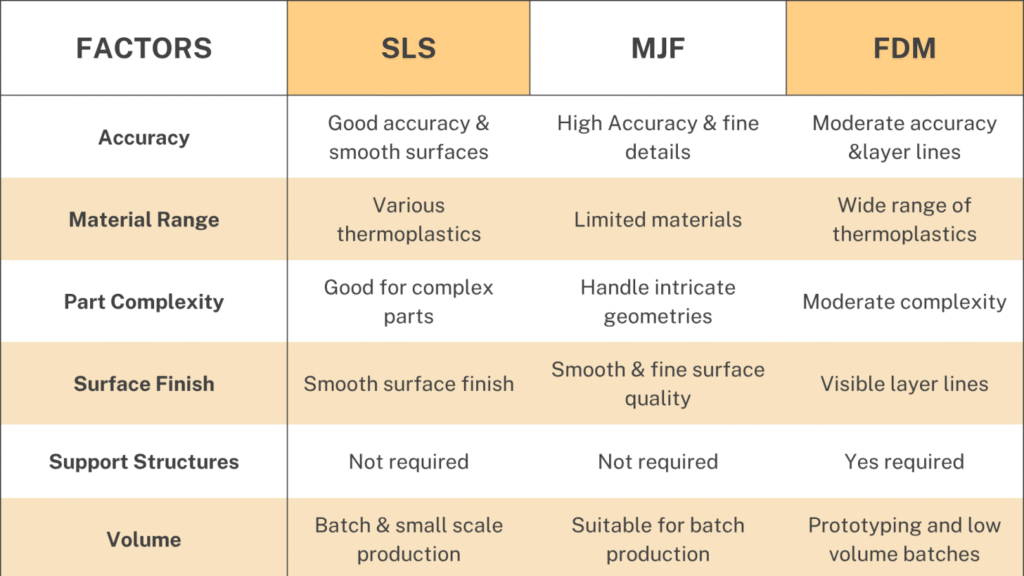

Comparison of SLS, MJF, FDM

Advantages of SLS 3D Printing

- No Supports Needed – Complex geometries, overhangs, and interlocking parts can be printed without extra structures.

- High Strength & Durability – SLS parts are isotropic, meaning they have uniform strength in all directions.

- Material Efficiency – Unused powder can be reused, reducing waste.

- Functional Prototyping & End-Use Parts – Ideal for high-performance applications in aerospace, automotive, and medical industries.

- Fast Production – Enables rapid iteration and on-demand manufacturing.

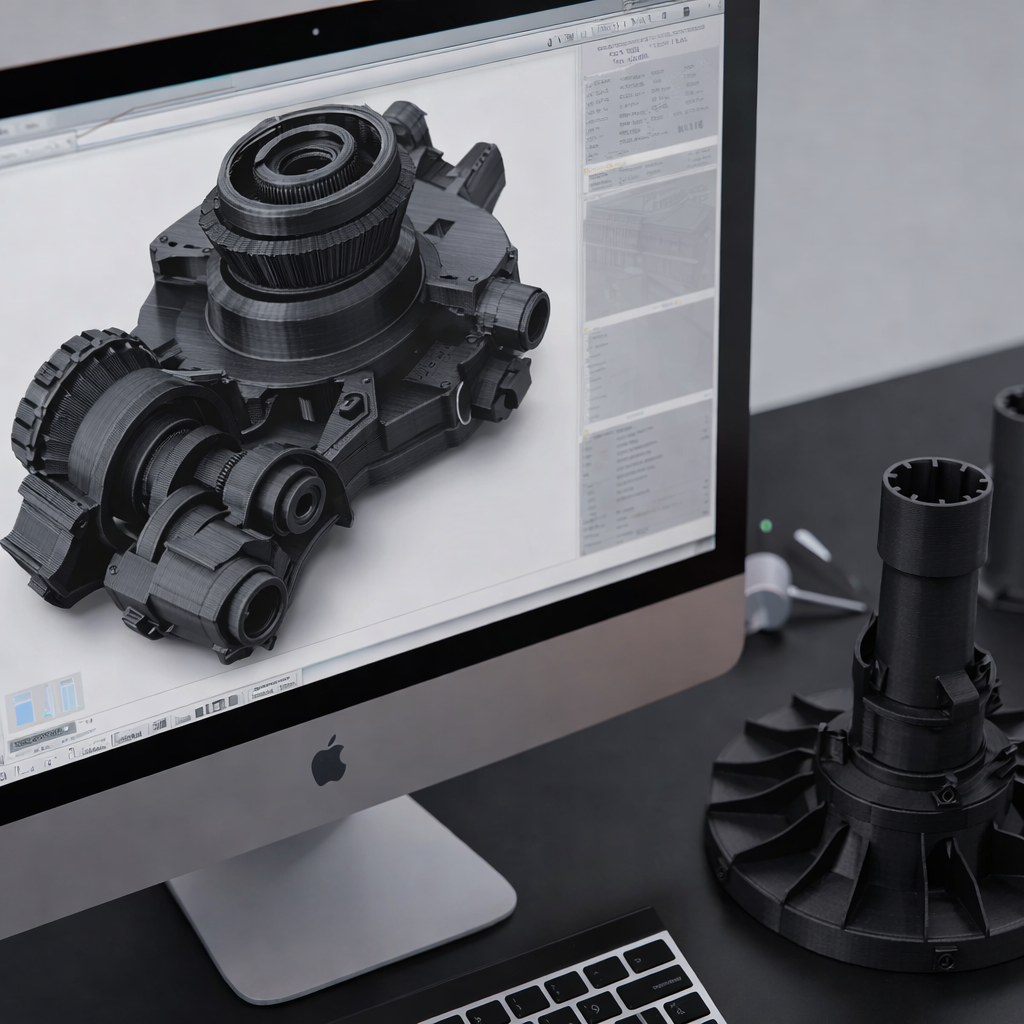

Applications of SLS

SLS is widely used across industries for:

- Aerospace – Lightweight, durable components

- Automotive – Functional prototypes & custom parts

- Medical – Surgical guides, prosthetics, and orthopedic devices

- Tooling – Jigs, fixtures, and custom manufacturing aids

- Consumer Goods – High-strength, complex designs

Why Choose Selective Laser Sintering (SLS)?

- Robust, High-Performance Parts – SLS produces strong, durable parts ideal for functional prototyping and end-use applications.

- Design Freedom and Complex Geometries – SLS can produce intricate and complex shapes without the need for support structures, which are often required in other 3D printing processes.

- No Support Structures – The surrounding powder bed in SLS acts as a natural support for the part during printing, eliminating the need for dedicated support structures.

- Reduced Manufacturing Waste– SLS produces less material waste compared to traditional subtractive manufacturing methods, making it a more sustainable option.

- Applications– SLS is used in various industries, including aerospace, automotive, healthcare, and consumer goods, for applications such as prototyping, tooling, and end-use parts.

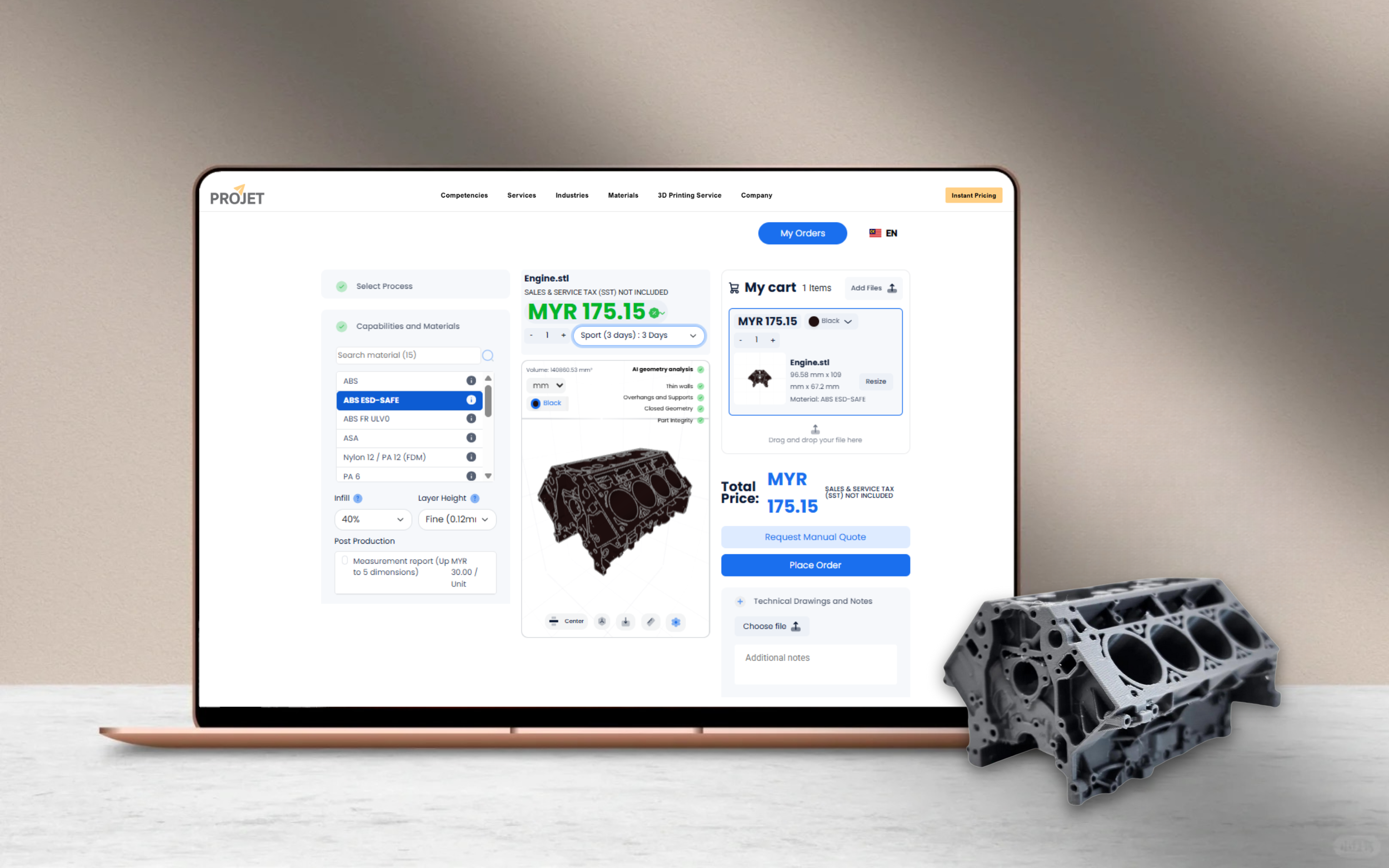

3D Printing Service Malaysia , 3D Printing service Singapore , 3D Printing service KL , 3D Printing service Selangor, 3D Scanning Malaysia

3D Printing Services

Instant Price