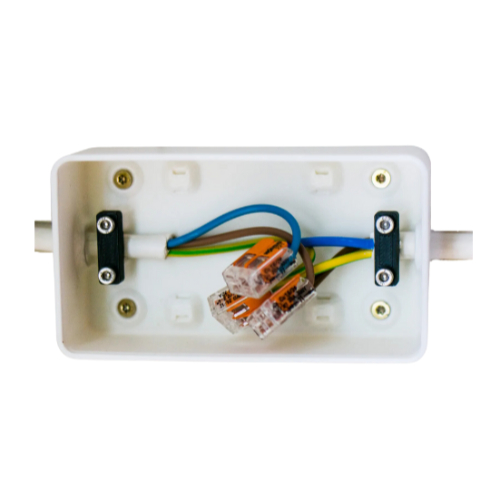

3D Printed High-Performance Consumer Electronics Components

That Monday Email:

“We need functional prototypes as it’s robust and will not become brittle over time.”

That was Dina, procurement at an consumer electronics companies, faced a common challenge in product development: balancing quality, lead times, and cost when moving from design to production.

Initially, she adopted FDM 3D printing for testing and prototyping. While this provided some early-stage benefits, it quickly became clear that the quality of final parts was insufficient for functional testing or small-scale production.

In search of an affordable, easy-to-use, SLS 3D printing , their team explored the available technologies. Their evaluation led them to Projet.

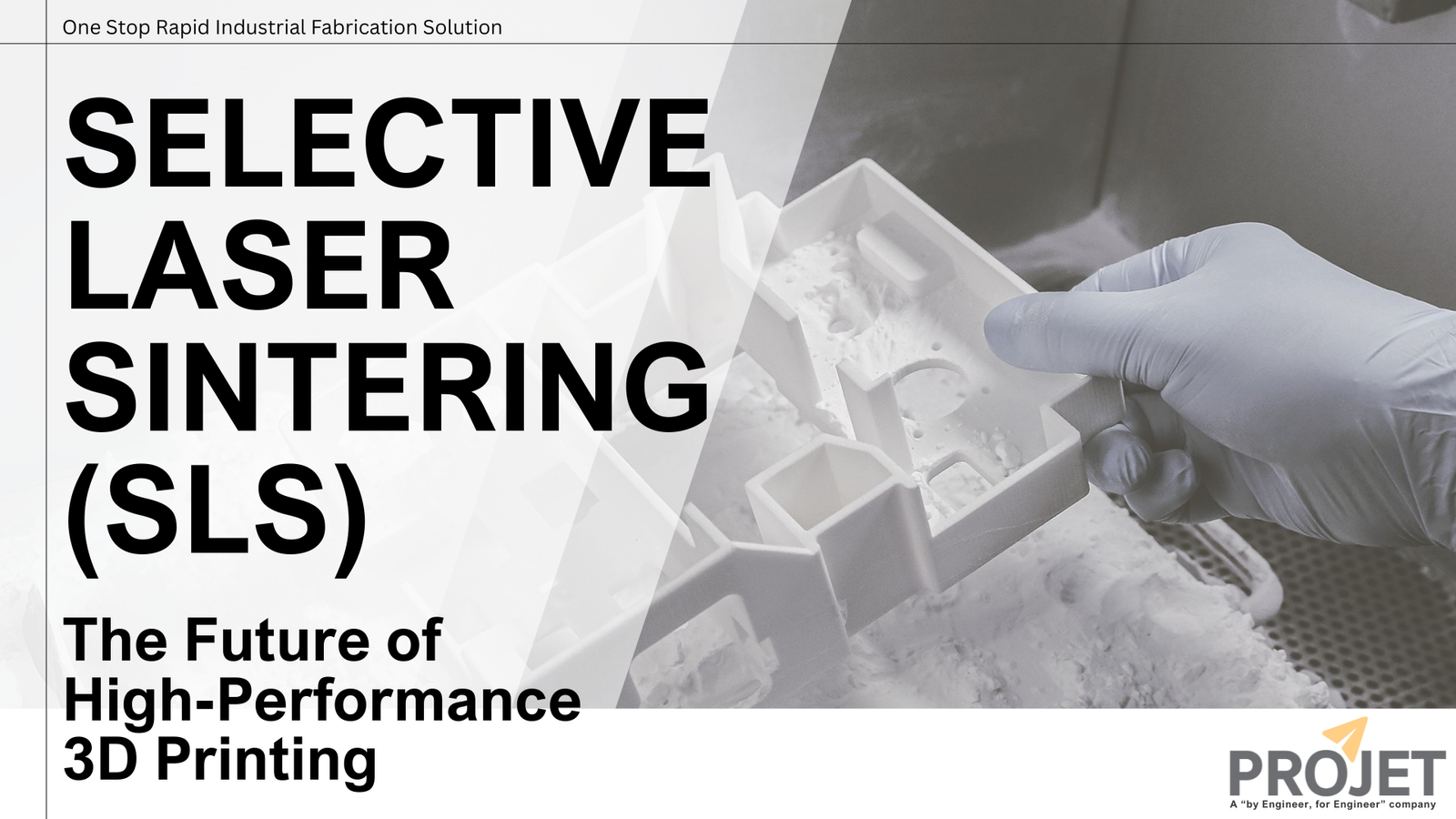

The Solution: Bringing SLS 3D Printing In-House

The team turned to Selective Laser Sintering (SLS) 3D printing for its ability to produce durable, high-accuracy parts without tooling.

✔ Industrial-grade quality: Parts robust enough for functional testing and small-scale production.

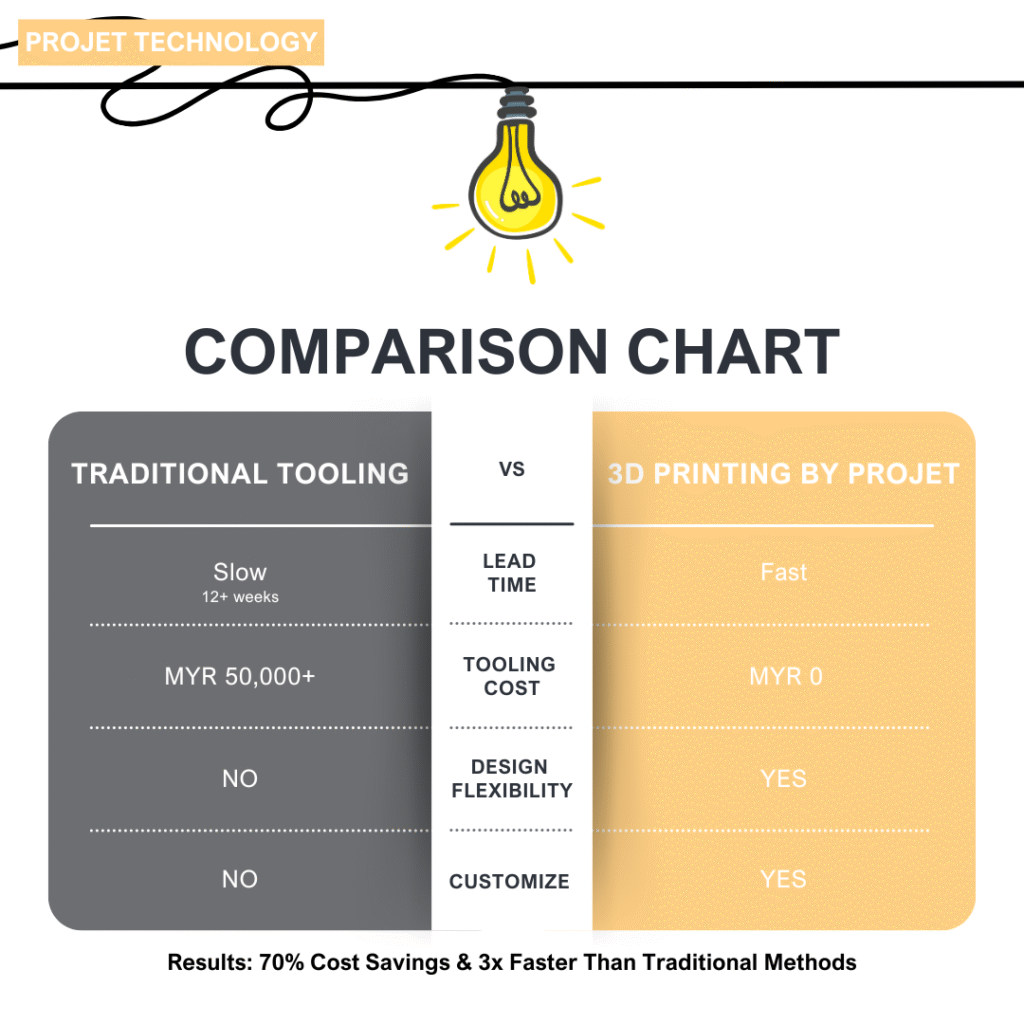

✔ Cost efficiency: Eliminated outsourced printing costs and reduced reliance on expensive molds.

✔ Speed: Cut lead times from weeks to days, accelerating iteration cycles.

By integrating SLS technology, Dina and her teams achieved:

- 70% faster prototyping for critical components like test fixtures and housings.

- 40% cost reduction in small-batch production by avoiding premature tooling investments.

- Rapid iterations enabled faster validation, reducing time-to-market for new solutions.

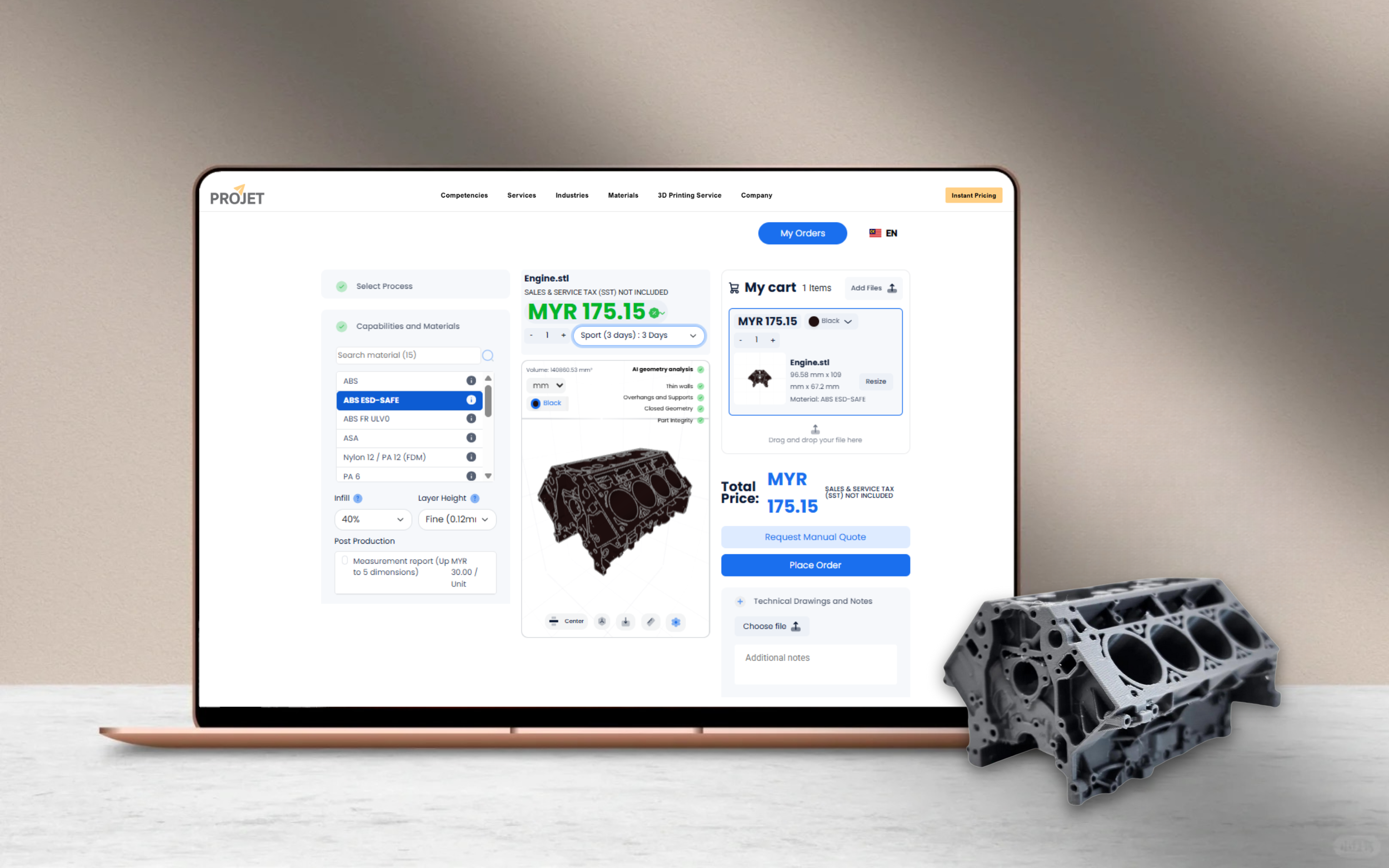

3D Printing Services

Instant Price